|

Douglas Instruments Douglas Instruments

Research Report 2, October 1995

IMPAX 1-5

Protein Crystallization System

Harvesting Crystals from Microbatch for Cryocrystallography

Crystals were harvested to a depression plate for heavy atom derivatization

Crystals were picked up on loop straight from microbatch wells for high resolution

studies

The use of oil did not interfere with the freezing process

Research by Elena Conti, Biophysics Group, Physics Department, Imperial College,

London SW7 2BZ

Report by Patrick Shaw Stewart, Douglas Instruments Ltd.

Introduction

The microbatch method has become well established in recent years both for screening of

crystallization conditions and for the production of diffraction quality crystals (Chayen

et al., 1992). A major improvement in X-ray diffraction data collection has come with the

introduction of cryocrystallographic techniques (Petsko, 1975; Teng, 1990) which greatly

reduce radiation damage to crystals. This raises the question whether cryocrystallography

can be used with crystals grown in microbatch. Researchers are concerned that the oil,

which is used to prevent evaporation from microbatch droplets, might interfere with

harvesting crystals using a fiber loop. The different geometry of the plates used might

also impede harvesting.

In a recent project at Imperial College, crystals were successfully harvested for

cryocrystallography into a depression well containing stabilizing solution for heavy atom

derivatization. They were also harvested straight from a microbatch well for high

resolution data collection.

Production of Crystals

Crystals of recombinant firefly luciferase were initially grown by the conventional

hanging drop vapor diffusion method, but these tended to dissolve when the temperature was

changed. Heat flows from the reservoir to the coverslip in hanging drop often cause

condensation on the coverslip. For example, taking a tray out of an incubator to view

under a microscope may cause condensation. This can dilute the droplet enough to cause

crystals to dissolve. Because the luciferase crystals were found to be unstable, it was

decided to change to the microbatch method.

Crystals were grown by the microbatch method in a medium containing protein, PEG 8000,

lithium sulfate, glycerol (5%) and ethylene glycol (12.5%). The volume of the droplets for

final optimization was 4 Ál. Needles at least 1 mm long were produced with average

thickness 40 - 80 Ám. Larger crystals having thickness up to 200 Ám were occasionally

obtained but these were very fragile and tended to crack when handled.

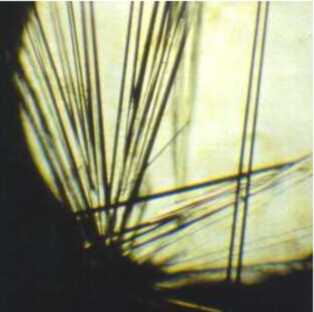

Crystals of firefly luciferase. Data could not be collected from VD

crystals which were unstable. Courtesy of E. Conti. Acta Crystallographica. D 52 (1996),

4, pp 876-878

Screening for heavy atom derivatives was carried out using the 40 to 80 Ám crystals.

Before flash-cooling, the crystals were immersed in the stabilizing solution containing

the cryoprotective agent for a few minutes. The presence of some cryoprotectant in the

crystallization conditions prevented damage of the crystals when they were transferred

into the solution used for freezing (10% glycerol and 12.5% ethylene glycol).

Harvesting for Heavy Atom Derivatization and Structure Determination

In order to produce heavy atom derivatives it is essential to find a harvesting

solution in which the crystals would be stable. In this case, a solution containing the

same ingredients as for crystallization was used, except that the PEG concentration was 5%

higher. The following procedure was used to harvest crystals:

1. Leaving the oil in position, a whisker from a cat was used to loosen up the crystals,

and to break the crystals into sections around 400 Ám long.

2. A standard micropipette with disposable tips was used to add 15 Ál of stabilizing

solution to the well containing crystals, and the solution was gently stirred.

3. The micropipette was used to withdraw 15 Ál of solution. Usually more than one crystal

was picked up.

4. The crystals were transferred to a depression well with 100 Ál of stabilizing solution

and then to the stabilizing solution containing the desired heavy atom.

5. Cryprotectant solution was added and the crystals were mounted on rayon loops and

frozen using standard techniques.

Potential heavy atom derivatives were screened at 6 ┼ resolution using in-house sources.

A better signal to noise ratio using synchrotron radiation allowed measurement of

diffracted intensities beyond 2.7 ┼ resolution. No increase in mosaicity was observed.

Harvesting Crystals Straight from Wells

In order to increase the resolution, data was now collected from the 200

Ám crystals using synchrotron radiation. These crystals were very fragile and could not

be handled freely, so it was decided to freeze them straight from the microbatch well.

This was achieved as follows:

1. Excess oil was drained from the microbatch HLA tray by tipping.

2. A micropipette was now used to add 15 Ál of cryoprotectant solution. This had the

effect of removing all but a thin film of oil from the droplet, while all the other wells

remained protected.

3. The droplet was stirred with a cat's whisker to detach the crystals, and the crystals

were broken into sections 400 Ám long.

4. The plate was inclined slightly and crystals were scooped with a loop directly out of

the droplets and frozen in the nitrogen stream.

The larger crystals and synchrotron radiation allowed data to be collected to 2 ┼

resolution.

Mounting from a microbatch well was found to be slightly more difficult than mounting from

a coverslip, mainly because of the geometry of the well. However, microbatch had other

advantages, including the exact knowledge of concentrations, and the ease with which

unmounted crystals could be transported to the synchrotron source.

References

The following papers give background information on cryocrystallography:

R. Henderson. Cryoprotection of protein crystals against radiation damage in electron and

X-ray diffraction. Proc.R.Soc.Lond. B 241, pp 6-8 (1990).

G.A. Petsko. Protein crystallography at subzero temperatures: cryoprotective motherliquors

for protein crystals. J. Mol. Biol. 96, pp 381-392 (1975).

T.Y. Teng. Mounting of crystals for macromolecular crystallography in a freestanding thin

film. J. Appl. Cryst. 23, pp 387-391 (1990).

For a description of IMPAX and the microbatch method see the following three papers:

N.E. Chayen, P.D. Shaw Stewart, D.L. Maeder, and D.M. Blow. An automated system for

micro-batch protein crystallization and screening. J. Appl. Cryst. 23, pp 297-302 (1990).

N.E. Chayen, P.D. Shaw Stewart, D.M. Blow. Microbatch crystallization under oil - a new

technique allowing many small-volume crystallization trials. J. Cryst. Growth, 122, pp

176-180 (1992).

N.E. Chayen, P.D. Shaw Stewart, P. Baldock. New developments of the IMPAX small-volume

automated crystallization system. Acta Cryst. D. 50 pp 456-458 (1994).

The following papers give examples of successful screening and optimization using

microbatch:

A. Zagari, L. Savino, S. Capasso, F. Sica, L. Mazzarella, A. Di Luccia, L. Ferrara.

Crystallization and preliminary X-ray analysis of the river buffalo (Bubalus bubalis L.)

BB phenotype carbonmomoxyhaemoglobin. Acta Cryst. (1994). D50, 778-780.

L. Pearl, B. O'Hara, R. Drew and S. Wilson. Crystal structure of AmiC: the controller of

transcription antitermination in the amidase operon of Pseudomonas aeruginosa. EMBO

Journal, vol. 13, no.24, pp.5810-5817 (1994).

Back to Research Papers Directory

|