4. "rMMS" and regular microseeding

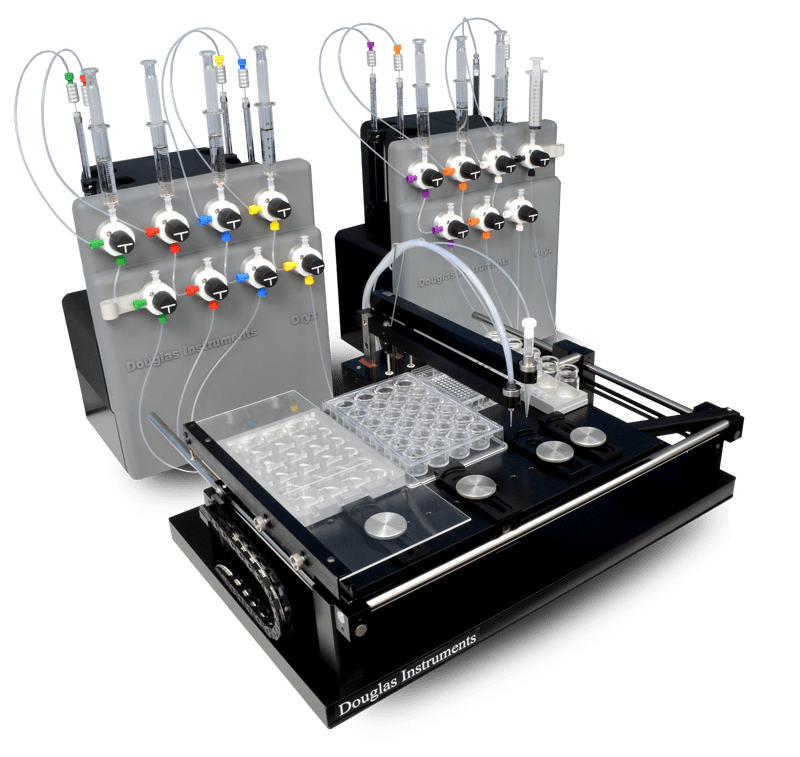

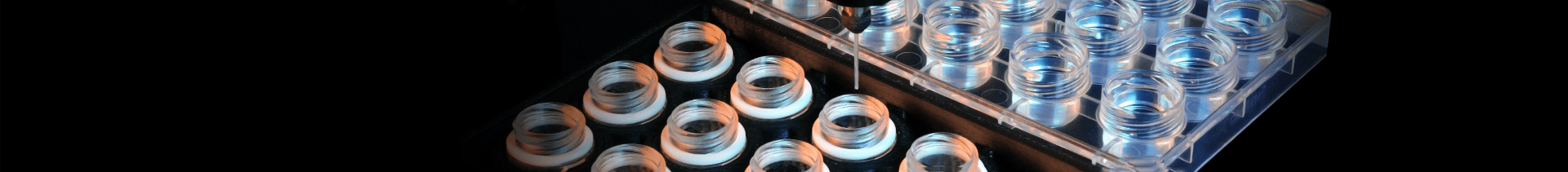

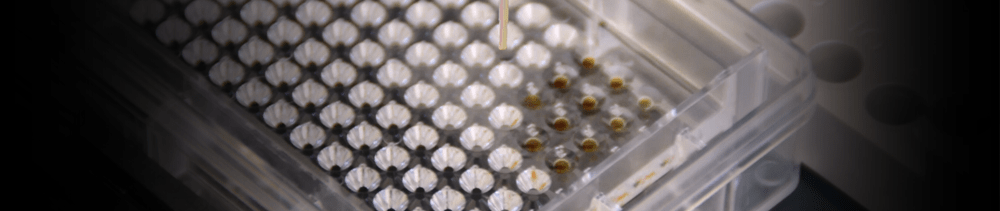

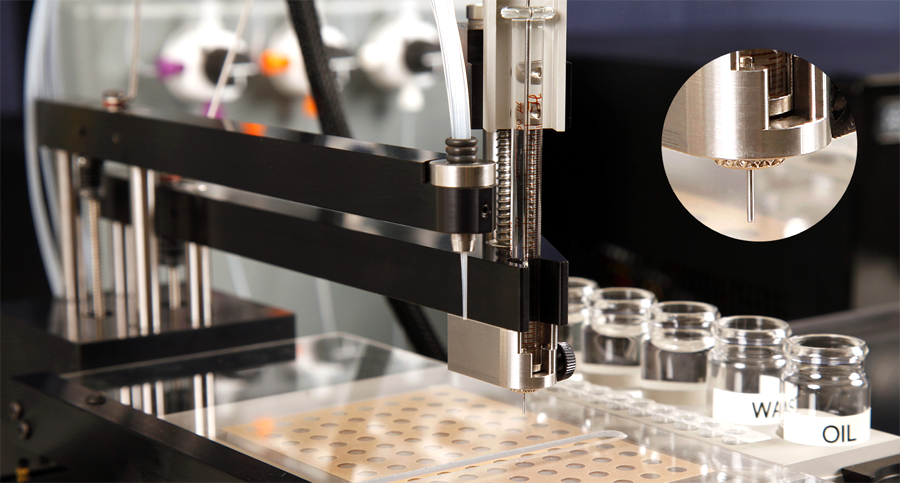

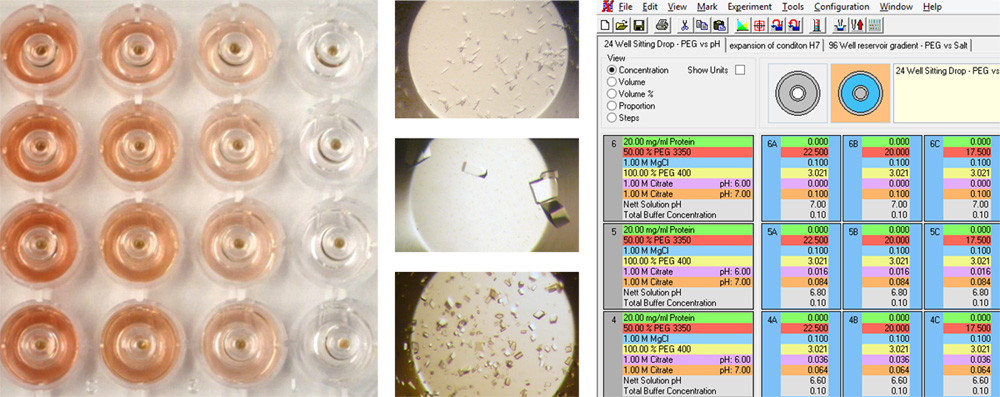

Since all Oryx systems use contact dispensing (the tip always touches

the plate) they give very reliable dispensing even when suspensions of

solid particles are used. This makes them ideal for microseeding

experiments. The technique of adding crystal

seed-stock to random

screens (rMMS) is a significant breakthrough in protein crystallization

that is very effective. For example, one industrial group

used the

method to solve 38 out of 70 structures generated in a four year period,

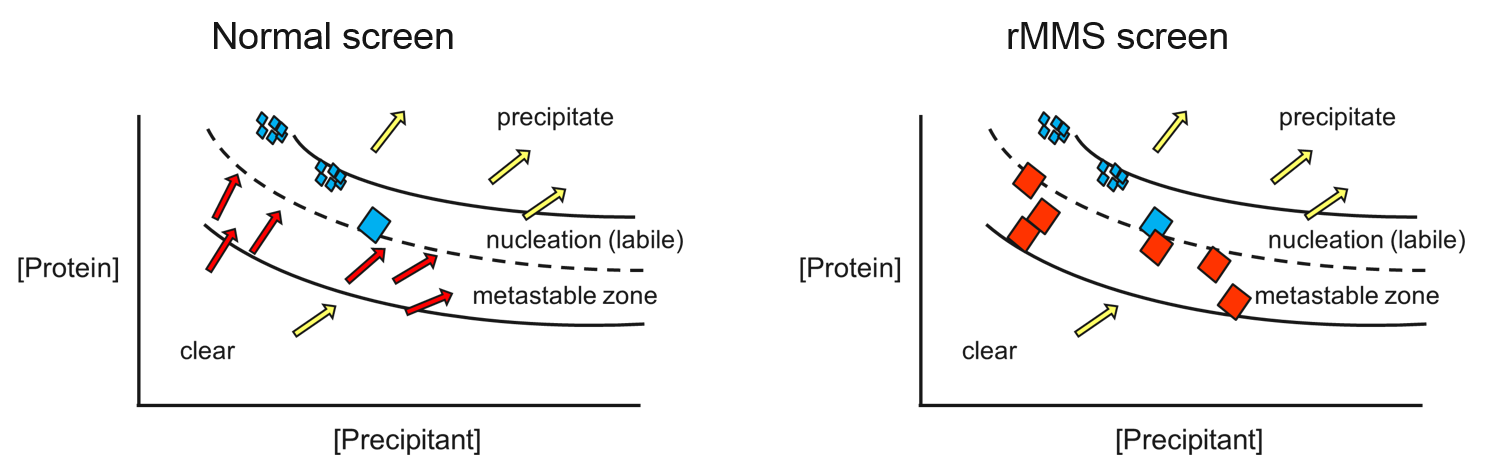

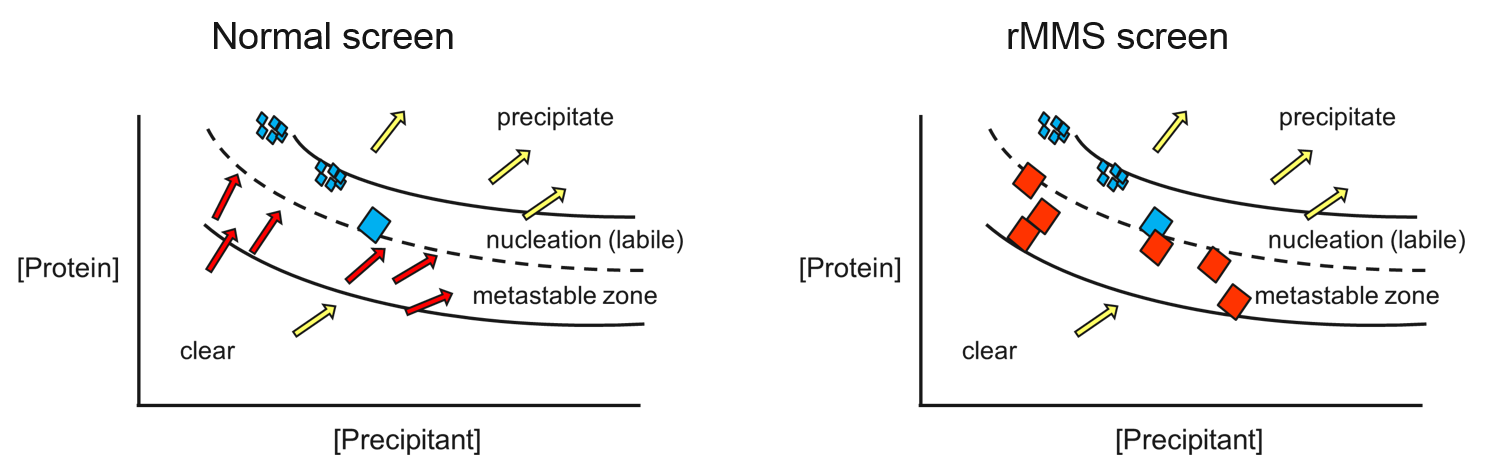

finding particular success with antibody complexes. rMMS not only

produces more hits, it also typically generates better-diffracting

crystals – because crystals are more likely to grow in the metastable

zone of the protein’s phase diagram (see below).

Note also that in cases where only one or a few crystals are obtained in

screening experiments, the seed stock that can be made is very valuable

– often more valuable than the protein sample. It is therefore a great

advantage to be able to use the smallest possible sample of seed stock.

Using any robot from the Oryx range, seeding can be performed in a whole

96-well plate using only 1.5 µl of seed stock. This is particularly

helpful for membrane protein crystallization projects because membrane

protein crystals are often unstable and it is helpful to make seed

stocks without diluting the original mother liquor.

Videos about rMMS : (1)

Introduction and theory. (2)

How to make Seed Stock for rMMS

Videos about rMMS : (1)

Introduction and theory. (2)

How to make Seed Stock for rMMS

5. Minimal protein or seed-stock wasted

Contact dispensing has another advantage: almost no protein remains in

the tip at the end of the experiment. Moreover, since only one

(multi-channel) tip is used, all of the protein for an experiment can be

placed in a single PCR tube, which also reduces waste. When they have

enough protein, most users set up 300 + 300 nl drops. For a 96-well

plate this requires only 29.4 µl of protein, i.e. only 0.6 µl is wasted.

If your pipette is accurate, there is no need to put more than the

specified amount into the tube!

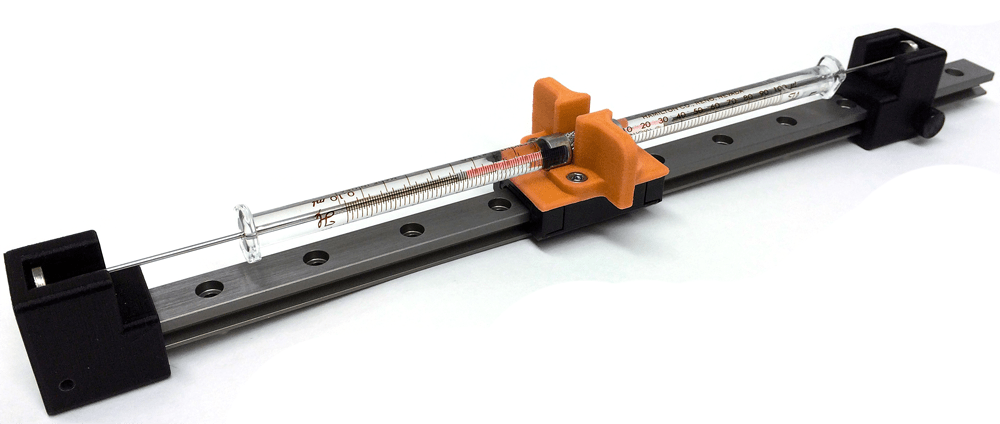

Similarly if 10 nl of seed stock is added to each drop, only about 1.5

µl of seed stock is required for a whole 96-well crystallization plate.

(It is helpful to dispense around 5 µl of screen solution on top of the

seed stock.)

6. Simple optimization experiments

All Oryx systems can carry out simple optimization experiments using three different approaches.

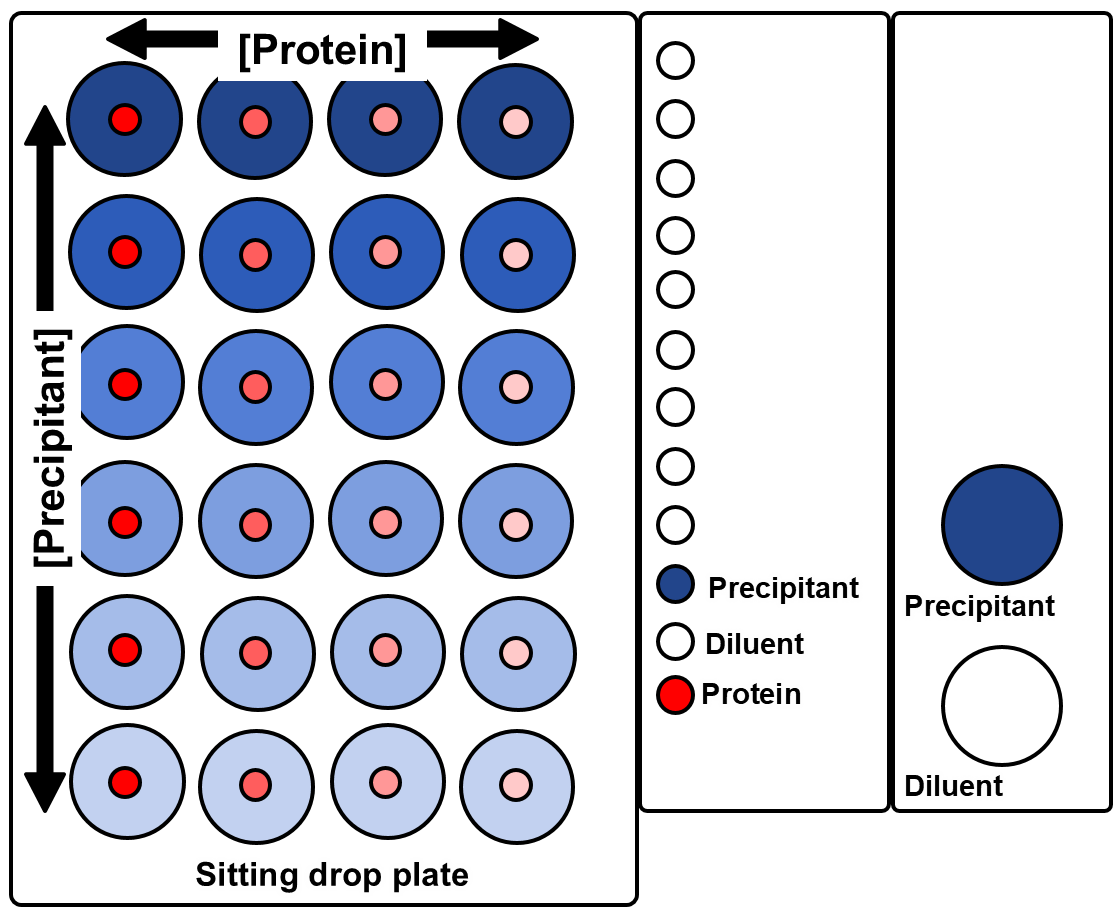

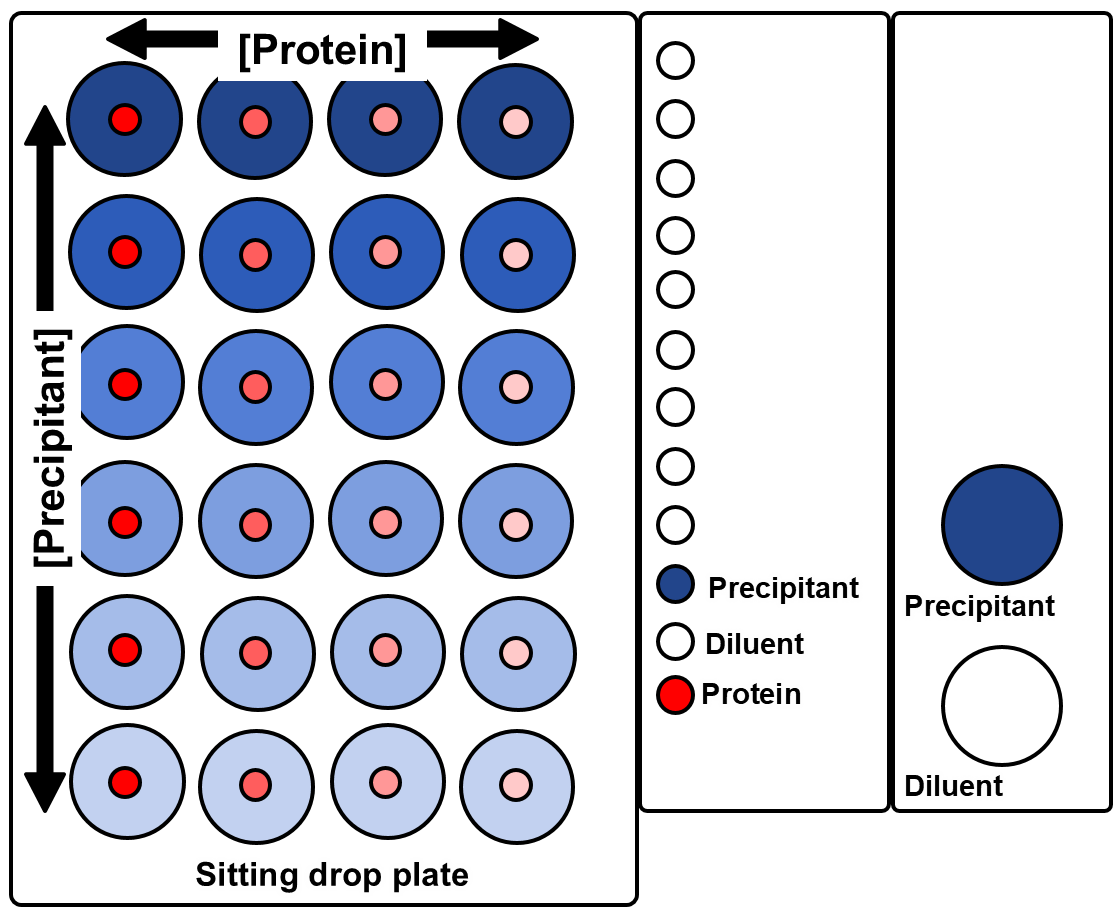

Simple 2D gradients

The standard screening software allows users to define simple 2D grid for sitting drop, *hanging drop and *microbatch-under-oil experiments (*Oryx4 and 8 only).

These experiments use three or four ingredients, the user specifies the minimum and maximum concentrations to be dispensed to the corners of a rectangular grid.

The software interpolates linearly between those conditions. (The user interface does not show the concentrations in intermediate wells, but the volumes dispensed to each well are shown in a report file.)

For vapor diffusion experiments, the robot dispenses ingredients to the reservoir well first, then loads protein and other precious solutions such as seed stock before dispensing all ingredients to the drop well simultaneously.

Note: Oryx Nano robots do not have a large volume dispensing channel and therefore can only dispense smaller volumes of ingredient solutions to the reservoir well.

Oryx Nano robots typically dispense a total volume of up to 15 µl to a small grid of e.g. 5x4 reservoir wells. Oryx4 and 8 robots typically dispense a total volume of 20 - 500 µl to each reservoir well.

(A more sophisticated approach to optimization that includes gradient experiments, multivariate optimization and reservoir filling with a greater number of ingredients is available with the Oryx8 – see below.)

Videos of 2D grid experiments:

Videos of 2D grid experiments:

(1)24 Well Hanging Drop.

(2)96 Well Sitting Drop.

(3)Microbatch-Under-Oil 2D Gradient.

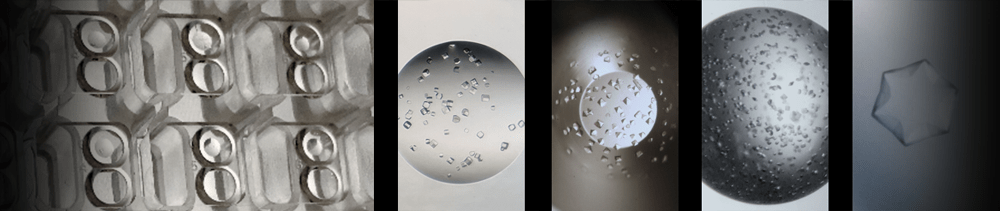

Cross-Matrix (additive) optimization

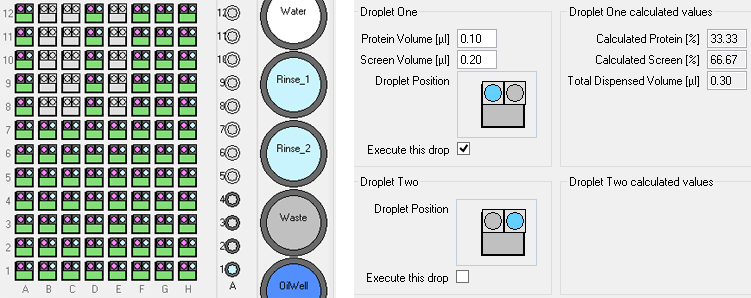

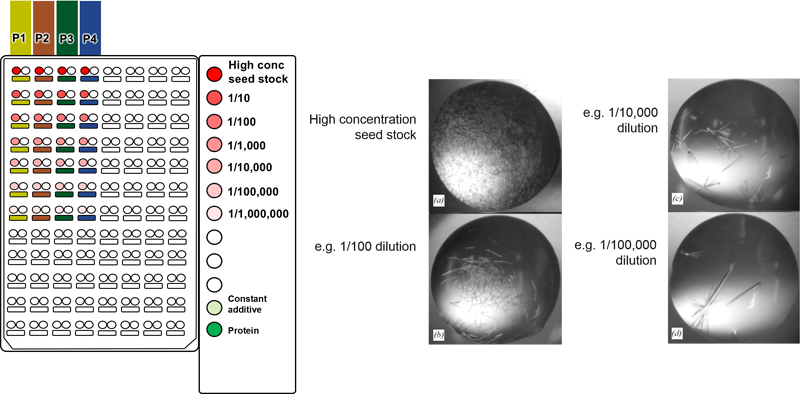

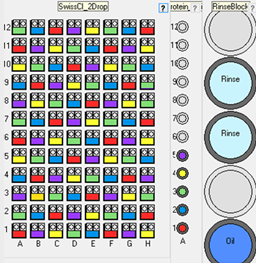

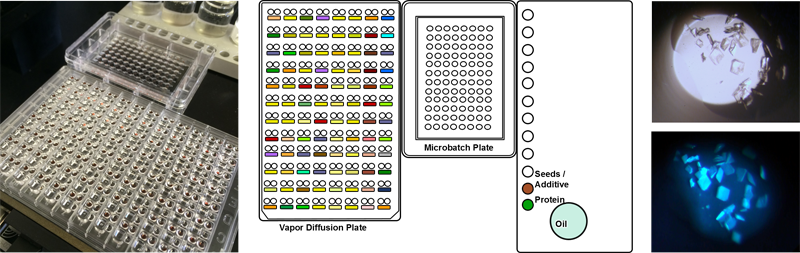

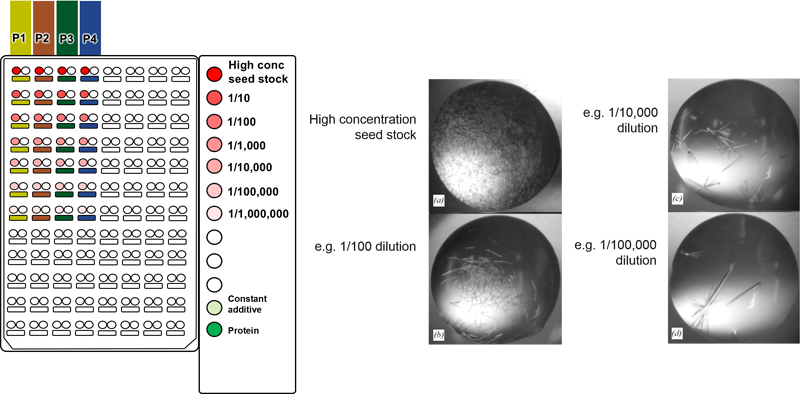

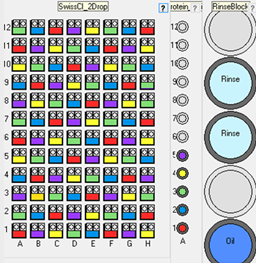

The systems' powerful “combinatorial optimization” approach allows a

different additive or seed-stock to be added to each row. Each additive

is picked up from the corresponding PCR tube on the right of the table

(A1, A2 etc. on the diagram below). By arranging e.g. precipitants in

columns (P1, P2 etc.), different combinations of precipitants and

additives can be tested very quickly. This is useful for reshuffling the

ingredients of several hits, so that ingredients that are not helpful

can be eliminated quickly, and trends can be identified. For example,

certain ingredients may encourage the formation of crystals with certain

morphologies.

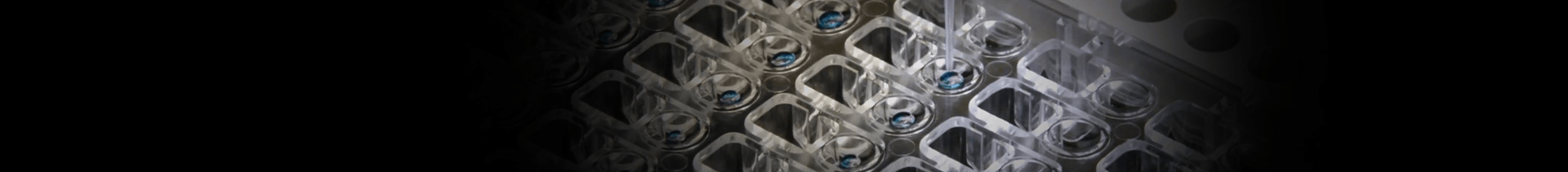

The combinatorial approach can also be used to systematically identify the appropriate dilution of a seed stock in a single experiment. We recommend using a highly concentrated seed stock

for routine rMMS screening, however this can result in showers of small crystals. It is often possible to optimize these conditions by diluting the seed stock to get around 5

crystals per drop (experiment with thermolysin shown above). For example, different concentrations of seed stock

could be placed in the PCR loading tubes shown 1 - 1E-6 dilution above. Four different conditions

could be placed into the four columns labeled P1 to P4 above.

This is a very effective way to get a really reliable supply of crystals

for data collection and soaking experiments.

Video about

Cross-Matrix Optimization

Video about

Cross-Matrix Optimization

Additive scatter optimization

Scatter up to 5 additives (e.g. seed stocks) evenly distributed across a vapor diffusion plate. The vapor diffusion plate would typically be pre-prepared

with a 2D gradient of precipitant against salt or precipitant against pH. The robot will then distribute up to 5 additives in a

pattern across the 2D gradient. This tests the additives across a range of concentrations.

This experiment would normally be used for testing up to 5 dilutions of seed stock. It could also be used to test other additives or protein concentrations.

Features of the Oryx4 and Oryx8 systems only:

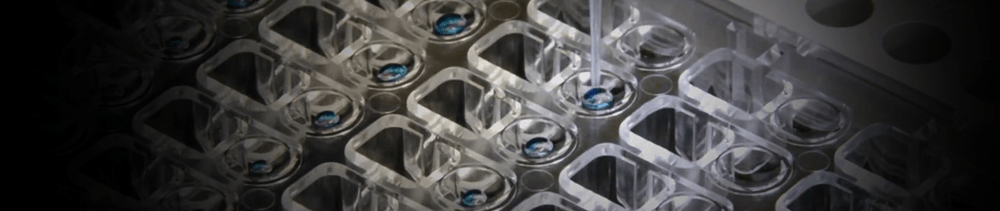

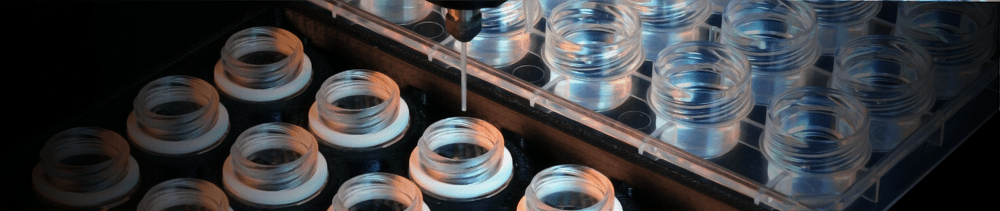

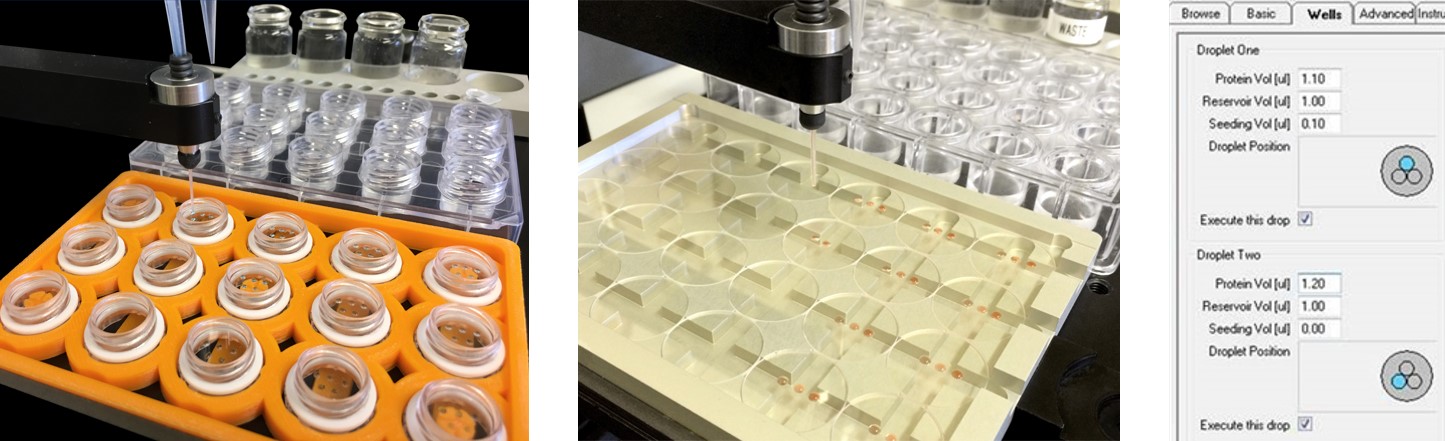

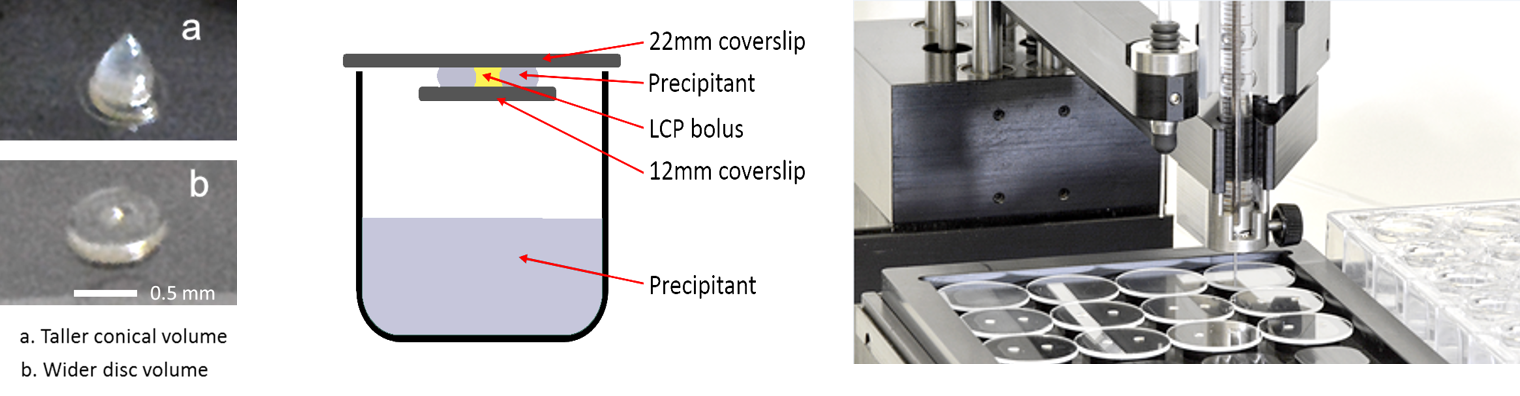

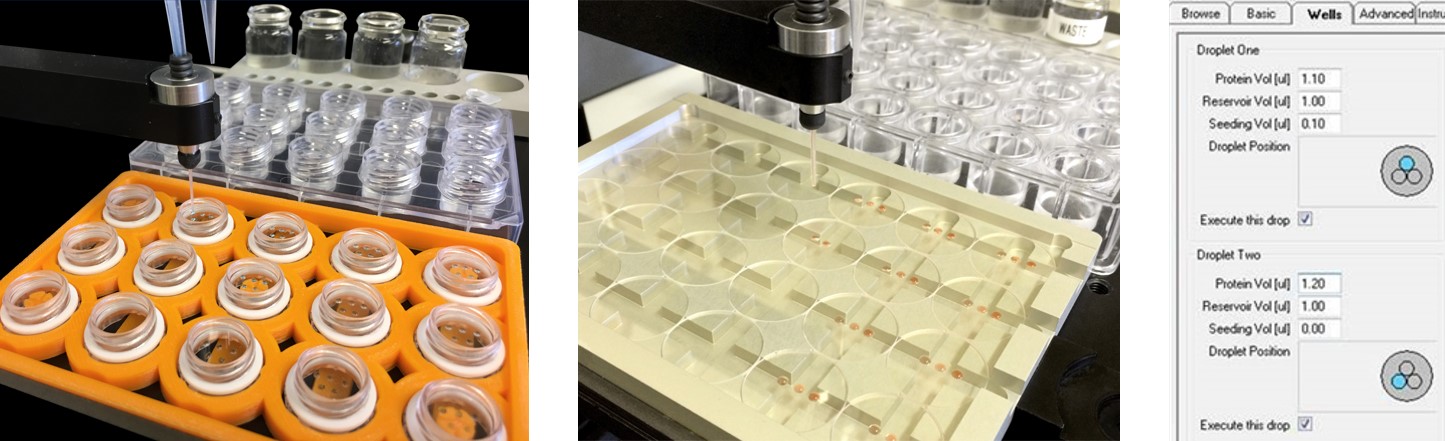

7. Hanging drop experiments

Oryx4 and Oryx8 can set up experiments with 22 mm, 18 mm and 12 mm cover slides as well as 15-well

EasyXtal plates, with up to 5 drops on each

cover slide. Volumes can range from 100+100 nl up to 8+8 µl (assuming 24 drops). You can also add one additive

to each drop with Oryx4, and up to five additives with Oryx8. This is very useful for leads that

are picked up in random microseeding experiments, where it may be necessary to add e.g. diluted seed stock to get crystals.

For example, in the experiment shown (below below), one drop has seed-stock, protein, reservoir solution; the second drop has no seed but

a little extra protein, while the third drop has no seed but a little extra reservoir solution.

You have to transfer the cover slides onto the reservoir tray by hand. After a few drops the experiment can be paused to allow the transfer.

Oryx8 can set up the reservoirs for optimization experiments, including 2D grid and multivariate experiments (see below). The hanging

drop capability is not available for the OryxNano.

Videos about hanging drop experiments: (1)

2D gradient - 24 Well Hanging Drop. (2)

24 Well Hanging Drop

Videos about hanging drop experiments: (1)

2D gradient - 24 Well Hanging Drop. (2)

24 Well Hanging Drop

8. Additive screening

Additive experiments are a well-known and effective approach to

optimization. Simply by adding a set of potential ligands or another

screen to a hit condition, crystals can often be optimized. Since they

have larger Plate Loaders, the Oryx4 and Oryx8 systems can accommodate

an extra 96-well plate containing additives to the right of the target

plate. The tip picks up e.g. 100 nl samples from the additive plate and

dispenses them along with protein and reservoir solution to the drops.

For initial screening relatively large volumes of additive are often

used, for example 300 nl (protein) + 100 nl (reservoir) + 200 nl

(additive). For example, these volumes could be used for an initial

screen with the Silver Bullet screen by Hampton Research. For final

optimization, smaller volumes of additive are often used, for example

300 nl (protein) + 200 nl (reservoir) + 100 nl (additive).

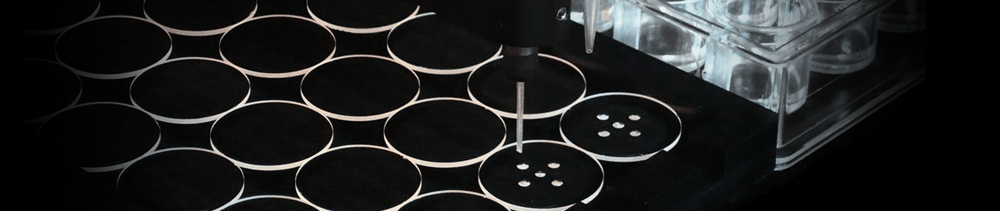

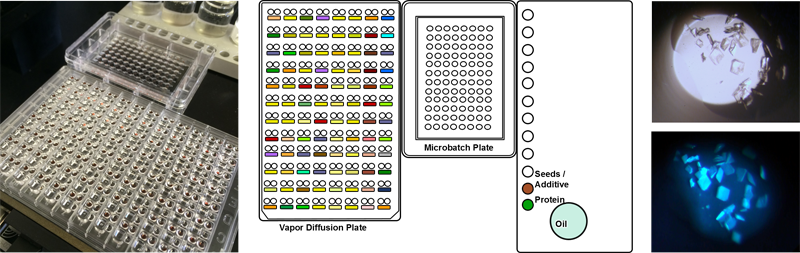

9. Microbatch-under-oil

Microbatch is a very simple approach to crystallization. Small samples

of protein (100 nl to 5.0 µl) are mixed with stock solutions in small

drops, and covered with oil to prevent evaporation. For screening

experiments it helps to use a 50:50 mixture of paraffin oil and silicone

oil. The silicone allows slow evaporation over about a month, which

gives a scanning effect across the phase diagram of the protein. For

optimization, pure paraffin oil can be used, which reduces evaporation

to a minimum. Studies have shown that microbatch finds as many or

slightly more hits that vapor diffusion, but the main advantage is that

(for reasons that may not be well-understood) certain proteins

crystallize much more effectively in microbatch than other methods. Microbatch can

help to protect sensitive proteins such as membrane proteins and

anaerobically-produced proteins because it reduces the oxidation and

gives thinner skins on the surfaces of drops.

A full set of experiment scripts for microbatch are available, including screening,

additive screening, 2D gradients and MMS microseeding. Oil is automatically dispensed onto the aqueous drop covering it immediately.

Using the Combined MB-VD experiment

it is possible to dispense two screening methods at the same time. It is also possible to dispense different drop ratios or add seed-stock or additive to any experiment or drop.

Videos about microbatch under oil experiments: (1)

Optimization. (2)

Screening (combined sitting drop and microbatch)

Videos about microbatch under oil experiments: (1)

Optimization. (2)

Screening (combined sitting drop and microbatch)

|